Hydrogels: Tomorrow’s Biomedical Solutions Today

Did you know that the hydrogels found in the contact lenses and cosmetics that many of us use every day are also crucial for the successful regeneration of our bodies’ vital internal organs? For many years, scientists have been meticulously studying the regrowing and repairing of damaged cells, organs, and tissues. A key breakthrough came when researchers established that the high water content of hydrogel polymer network structures’ make them useful for regenerative medicine.

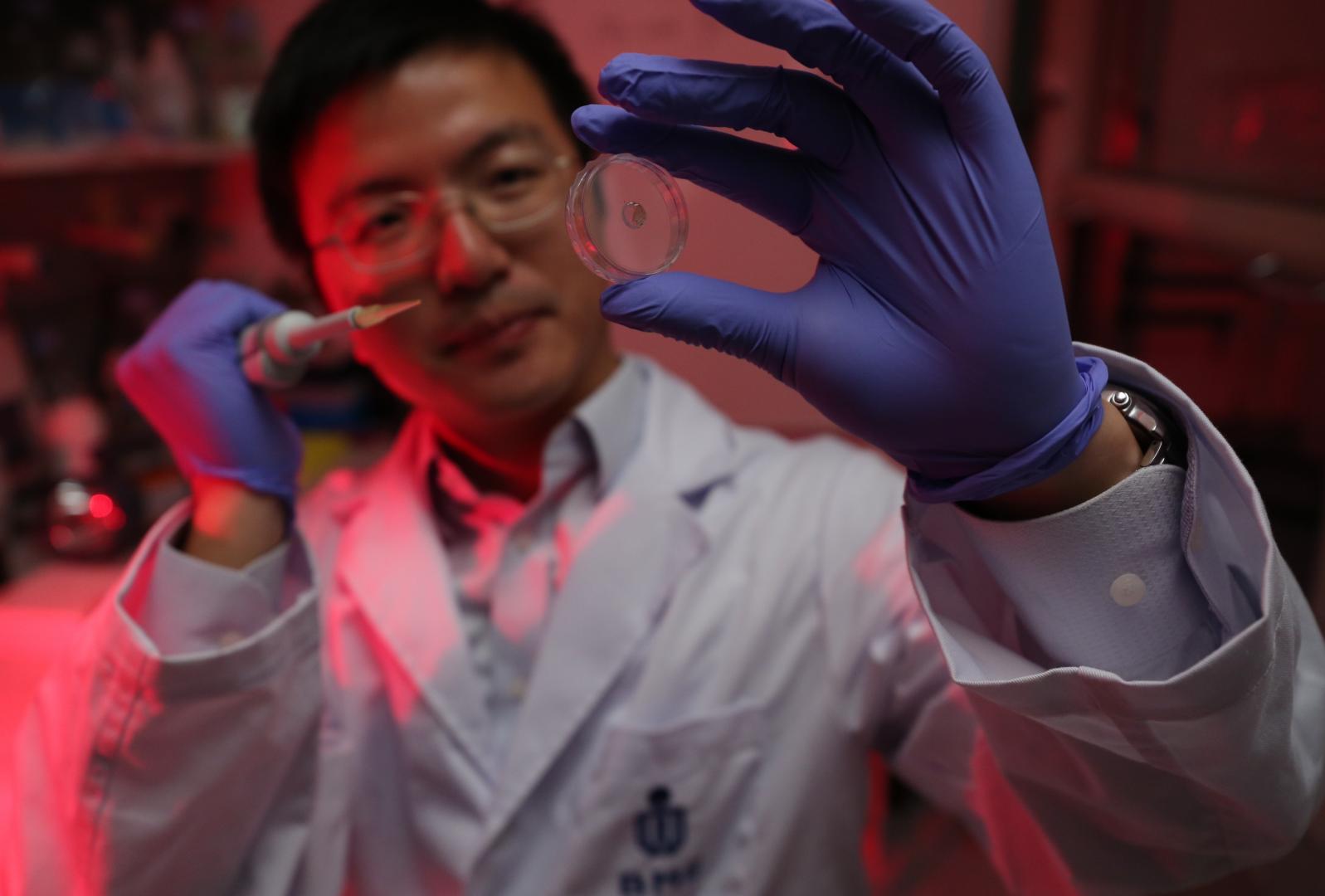

In 2019, HKUST School of Engineering postgraduate student Kachin WONG began studying a paper by Prof. SUN Fei of Chemical and Biological Engineering about smart hydrogels. The professor’s insights into such materials immediately inspired Kachin to start investigating their immense biomedical potential.

“Essentially genetically engineered elastin-like proteins, the smart hydrogels pioneered by Prof. Sun closely resemble human tissues in terms of composition,” says Kachin admiringly. “These similarities not only benefit current biomedical research, but also help pave the way for next-generation therapeutics.”

Pushing the biomedical engineering envelope

While Kachin had dreamt of studying medicine since secondary school, his less-than-expected public examination results seemingly put a stop to his ambitions. Fortunately, his disappointment turned to joy when his biochemistry and cell biology studies at HKUST enabled him to enter the world of biotech.

After earning his BSc, Kachin began working toward a Master’s in Technology Leadership and Entrepreneurship, HKUST’s unique training program for business visionaries wishing to prototype pioneering innovations. His ultimate aim was to equip himself with the skills needed to successfully market biotech products.

Structured around an insolvable three-dimensional network, smart hydrogels can absorb large amounts of water. This provides an excellent microenvironment to promote the engineering of tissues and organs with the commercial potential needed to transform the future of healthcare.

If hydrogels are to do their job, Kachin says, they must first be highly biocompatible – just like those developed by Prof. Sun. Conventional alternatives made of synthetic polymers or biological extracts such as animal collagen, by contrast, are likely to cause their recipients to suffer allergies or transplant rejection.

Realizing the innovation’s great value, Kachin promptly asked to join Prof. Sun’s research team.

The professor subsequently introduced Kachin to fellow PhD students, WANG Ri and YANG Zhongguang, and tasked the three with accelerating hydrogels’ possible commercialization. Prof. Sun’s support marked Kachin’s first step along his entrepreneurial journey, enabling his mentee to achieve his youthful dream of a career in the medical sector.

The new collaboration’s primary goal was to maximize the potential of the new biomedical material. “The beauty of using proteins to make hydrogels is that we take advantage of the ecological diversity of Mother Nature. It opens up new thinking about material design, materials biology and biomedical applications,” says Prof. Sun.

“In theory, smart hydrogels empower the healing process by carrying and delivering stem cells to damaged organs on demand. As a result, organ transplantation may no longer be patients’ only treatment option in the future,” says Prof. Sun excitedly.

In addition to advancing regenerative medicine, hydrogels’ responsiveness to external stimuli makes them the ideal channel via which to carry drugs to achieve better therapeutically beneficial outcomes. “Hydrogels can be administered via injection into the body,” says the professor. “By irradiating the injected area with light, we can then trigger the controlled, sustained release of drugs.”

Transforming aspirations into actualities

Under Prof. Sun’s guidance, Kachin and his colleagues co-founded a biotechnology start-up called SPES Tech in 2019. Among the many applications of the material, the enterprise is striving to commercialize the technology to bring convenience to biomedical research sub-specialities such as cell culture.

After two years of intensively researching “LitGel”, the company’s hydrogel flagship, SPES Tech is now overseeing the product’s pilot run via its recently opened Shenzhen branch. The first batch of “LitGel” is scheduled to go into mass production before the end of summer 2022.

Now dividing his time between Hong Kong and Shenzhen, Kachin is optimistic that their encouraging progress to date will further extend the burgeoning interest in hydrogel reagents across the Greater Bay Area. “The pandemic has accelerated the demand for hydrogel reagents, because more and more institutions are now looking to investigate three-dimensional cell cultures and micro-organs for therapeutic purposes,” says Kachin.

Since SPES Tech’s hydrogel products can recreate in-vivo environments similar to human tissues, researchers can more closely and effectively study cells behavior during cultivation. Capitalizing on such materials’ excellent light sensitivity, “LitGel” is the first product of its kind to leverage light to harvest cultivated cells harmlessly. All of which means cells can now undergo three-dimensional culturing before being released for subsequent experiments on a non-invasive basis, avoiding any loss of viability.

“The fact that these cell culture models also simplify evaluations of how drugs go to work in patients’ bodies makes it easier to test various drug candidates in order to find the one best suited for further development,” says Kachin.

Kachin believes that such time savings will facilitate a full spectrum of medical research spanning everything from oncology and regenerative medicine to drug discoveries. Best of all, as “LitGel” is available in separate components, it offers even more flexibility for researchers wishing to adjust its composition and tailor solutions that precisely mirror specific project needs.

Kachin and his colleagues’ diligence in pioneering simple, practical, and flexible cell culture work solutions has won numerous accolades. In addition to the coveted President Award at the 2020 HKUST-Sino One Million Dollar Entrepreneurship Competition and the Innovation Project Special Award of 2019’s 5th Hong Kong Student Innovation and Entrepreneurship Competition, the team also won places on several incubation programs including global tech giant Merck’s China Accelerator, HKSTP Incu-Bio, HKTDC Startup Express, and most recently Qianhai Shenzhen-Hong Kong Innovation and Entrepreneur Hub.

Given the considerable costs the company incurred as a result of pandemic-related disruptions to essential cross-boundary logistics, Kachin admits that financing remains a major hurdle. “As potential incubators and institutions may not immediately grasp the lucrative potential of deep tech advances like cell cultures, we all have to work doubly hard to secure financing to continue our work.”

The recipient of seed money to fund essential lab resources and equipment, SPES Tech’s is one of the many beneficiaries of HKUST’s Technology Transfer Center and Entrepreneurship Fund.

“When we first started, we were well aware building a biotechnology start-up from scratch would be a huge challenge,” recalls Kachin. “With the benefit of hindsight, I would have followed exactly the same path as I find identifying practical uses for research so personally fulfilling.”

Kachin remains very thankful to Prof. Sun for giving him continued guidance and introducing him to a broad network of contacts featuring many industry leaders and valued collaborators. Chief among them is Assistant Professor Angela WU of HKUST’s Division of Life Science, who is currently leading a research project on 3D vasculature culture using hydrogels.

“For students, embarking upon a business venture can initially seem very intimidating. Happily, Prof. Sun has given me a lot of support,” Kachin says gratefully. “He’s only a few years older than me, so I always feel like his friend rather than his student.”

Still pursuing his Bioengineering PhD dream at HKUST, Kachin remains determined to commercialize still more biotech research outcomes achieved in the laboratory. In the future, he and his fellow researchers are also intent on expanding hydrogels’ vast application potential into useful tools for personalized medicine, a trend now sweeping the wellbeing industry.

“While it takes time to harvest one’s experience, I am incredibly enthusiastic about hydrogel’s prospects,” Kachin says firmly.